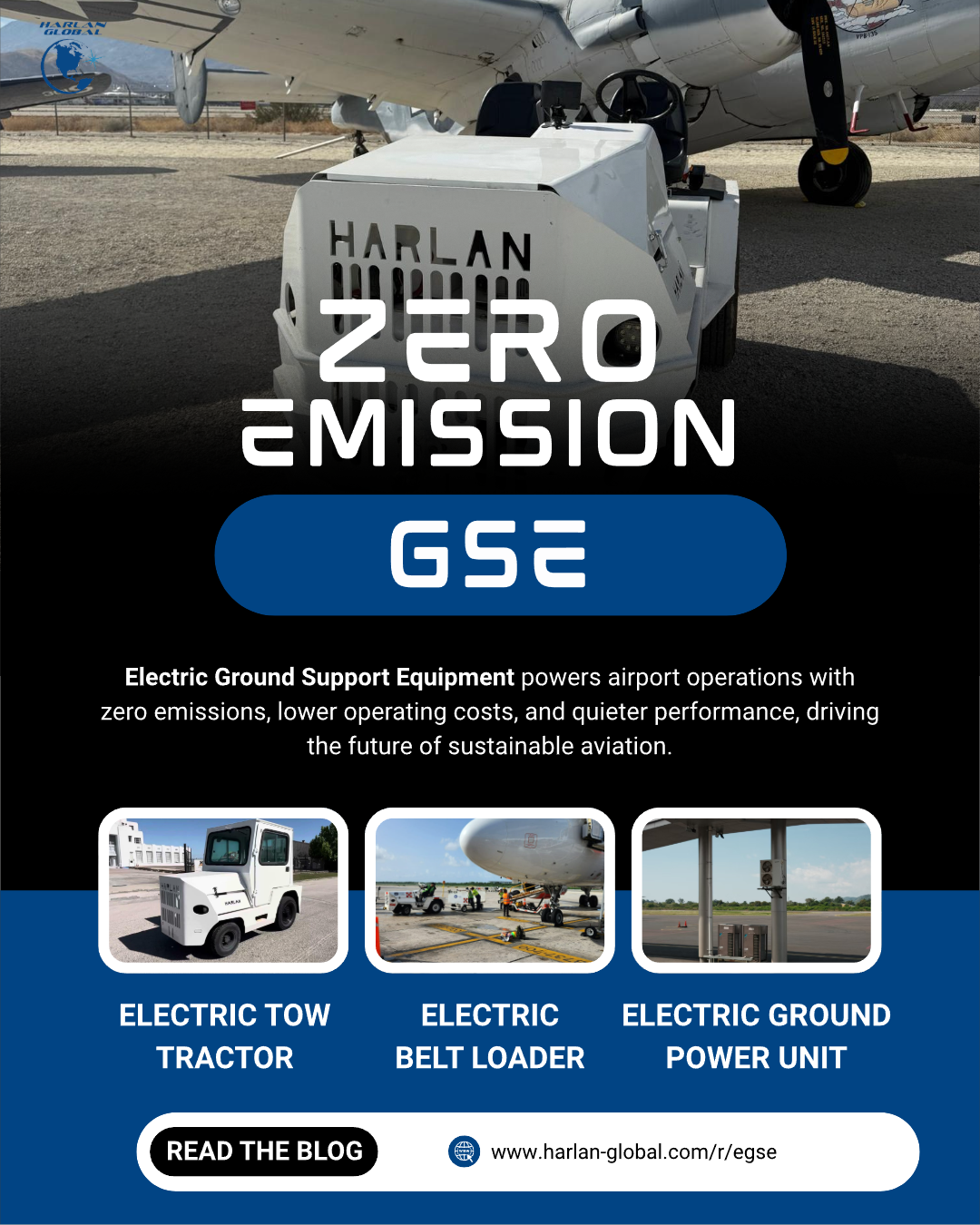

In a world where efficiency and sustainability are becoming increasingly important, airports are accelerating the transition to electric Ground Support Equipment (GSE). These machines, designed to operate at the very heart of airport ground operations, not only reduce environmental impact but also improve productivity and lower long-term operating costs.

The Role of GSE in Airport Operations

Ground Support Equipment is the invisible engine that keeps airports running. From tow tractors that move cargo and baggage to units that supply power and essential services to aircraft, GSE ensures every flight departs and lands safely and on time.

Traditionally, much of this equipment has relied on diesel or gasoline engines. However, the demand for cleaner and quieter operations has driven the shift to electric GSE, marking the beginning of a new era in ground handling.

Key Advantages of Electric GSE

Zero Emissions at the Point of Use

Eliminating exhaust gases on the ramp directly improves air quality at airports and surrounding areas.

Lower Operating Costs

Electric motors require less maintenance than combustion engines, meaning fewer unplanned downtimes and reduced spending on spare parts.

Quiet Operation

Lower noise levels on the ramp improve working conditions for ground crews and reduce noise pollution for passengers and nearby communities.

Regulatory Compliance

More and more airports and aviation authorities are imposing strict environmental regulations. Transitioning to electric airport ground support equipment ensures compliance and enhances corporate image.

Why the Shift Is Happening Now

Adopting electric tow tractors and other electric ground support equipment is not only an environmental decision but also a smart business strategy. With air traffic growing and increasing pressure to reduce emissions, companies investing in electric GSE today are securing their competitive edge for the future.

Sustainability in Action: Why Electric GSE Is the Future of Airport Ground Support