Behind every electric ground support tractor is a team of welders, technicians, assemblers, and quality control specialists working together to build equipment that performs in demanding airport environments.

At our Kansas City, Kansas facility, approximately 50 employees support the design, fabrication, assembly, and testing of electric tractors used in baggage and cargo operations across the aviation industry. Most units are built to order, allowing us to tailor configurations to specific operational needs.

This is what a typical day of building an electric tractor looks like.

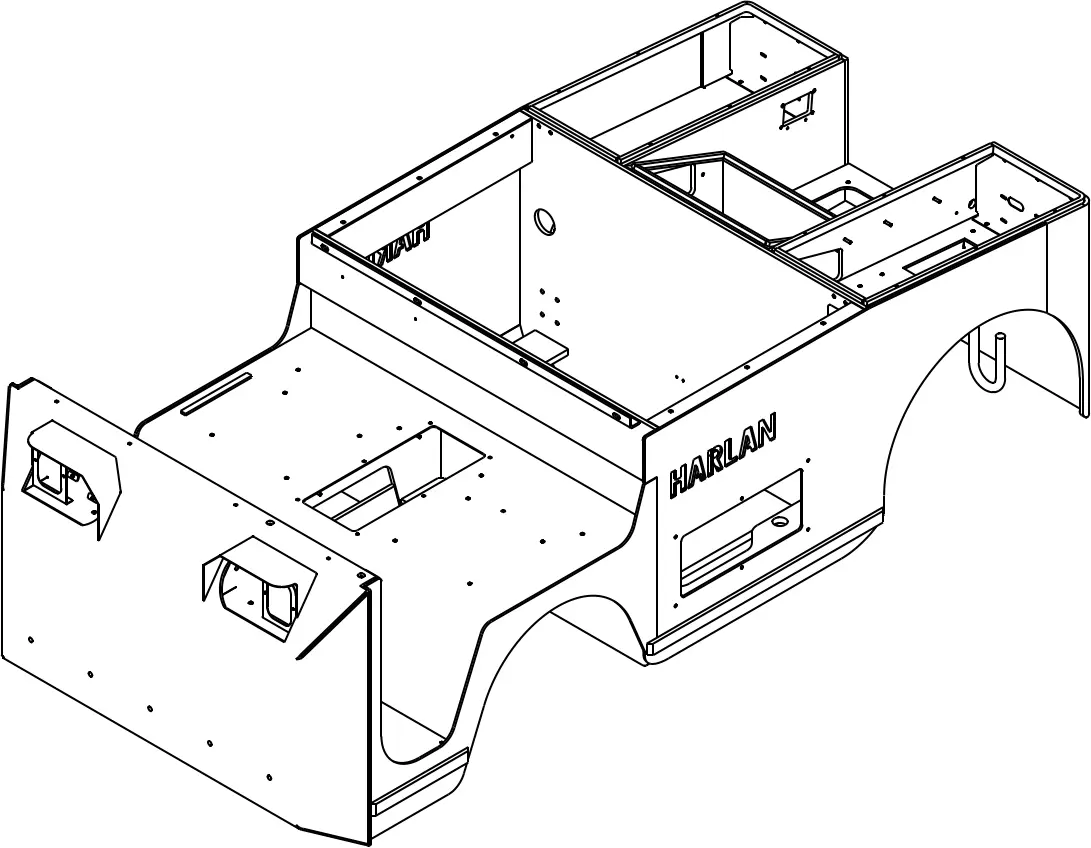

Frame Preparation and Welding

The build process begins with the frame. While most structural components are sourced through trusted partners, frames are now delivered pre-welded and ready for assembly at our facility.

Skilled welders assemble and reinforce the chassis to ensure durability under continuous ramp use. Because ground support tractors operate in high-load, high-cycle environments, structural integrity is critical from the very first step.

Once welding is complete, units move to paint preparation before receiving a durable finish designed to withstand outdoor airport conditions.

Assembly Line Integration

After fabrication and paint, tractors move into assembly. While certain stages operate at individual stations, the integration of major components follows a production flow similar to an assembly line.

Purchased components are combined with parts manufactured in-house. This hybrid approach allows us to maintain quality control over critical elements while leveraging proven industry components where appropriate.

During this phase, technicians install and integrate:

- Electric drivetrain components

- Highly-efficiency drive axle with integrated AC motor

- Wiring harnesses and electrical systems

- LCD dash display and operator controls

- Programming of controls and calibration of system settings

- Driver and passenger seating with retractable seatbelts

- Rear mount hitch configurations

-

Testing and verification of all functional systems

For models such as the HLE, lithium-ion battery power supports longer duty cycles between charges while maintaining a low-maintenance electric package.

Optional configurations may also be installed at this stage, including:

- Complete cab assemblies

- Heat and defrost systems

- Mirrors and beacons

- Suspension-style seats

- Keyless or keyed master switch systems

- Various hitch configurations

Because most units are built to order, this stage often reflects customer-specific requirements. In some cases, we collaborate directly with customers to design specialized configurations tailored to unique operational needs.

Electrical Systems and

Operational Checks

Before any tractor leaves the facility, its systems are thoroughly reviewed. Inside the plant, technicians verify electrical performance, safety systems, and component integration.

Standard safety features such as the driver seat kill switch, LED lighting systems (headlights, tail/stop lights, back-up lights), and forward and reverse inching controls are checked to ensure proper functionality.

This controlled indoor environment allows for detailed system verification before moving to full operational testing.Quality Control and Road Testing

After system verification, each unit undergoes quality control review. Tractors are positioned on a raised inspection ramp where final checks are performed.

From there, the equipment moves outdoors for road testing. A designated quality-control operator drives the tractor to confirm steering response, braking performance, acceleration, and overall operational feel.

This final step ensures that each unit performs as expected in real-world ramp conditions before delivery.

Built for Real-World

Aviation Operations

Most electric tractors produced at our facility can be completed within a day, depending on configuration and production flow. The combination of in-house fabrication, structured assembly, and comprehensive testing allows us to maintain consistency while adapting to customer-specific requirements.

Electric ground support equipment must perform reliably under demanding schedules and continuous use. By combining hands-on fabrication, practical engineering, and layered quality checks, our team builds tractors designed to support baggage and cargo operations with efficiency and durability.

As aviation operations continue to evolve toward electrification, the focus remains the same: build equipment that works—every shift, every day.

A Day Inside Harlan Global Manufacturing: How Our Electric Tractors Are Built